Union Fitting:

Union are hundreds of parts within a plumbing and piping system that make it work. What makes the very critical aspect of a system not noticed so often is fitting. So, in this post, Union we will discuss how they’re used, their types, Union Applications, and advantages, as well as some tips about installation and maintenance.

What Are Union Fittings?

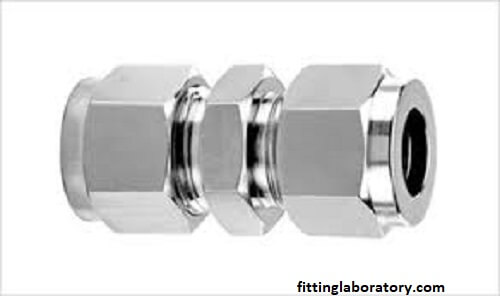

Union Fitting:

A fitting is one of the connectors in plumbing that connects two pipes or fittings at the same time and makes easy disconnection when it is intended to be done. Comparatively, other kinds of fittings may require cutting or unscrewing of pipes, while can easily be separated hence making them ideal for maintenance and repair works. They are mostly three parts, that is the two end fittings, and a middle nut holding them together.

Types of Union Fittings:

Union Fitting:

fittings come in a variety of styles and materials, providing the diversity needed in plumbing and piping applications. The following are among the common ones:

1. Metal Unions:

Metal are extensively applied in plumbing and industrial services. They may be produced in brass, stainless steel, or carbon steel, depending on the desired properties that each offers:

The brass is renowned for impressive corrosion resistance and permanence. They have a higher usage rate in water and gas lines.

Stainless Steel Unions:

Stainless steel is recommended for applications that require maximum anticorrosive properties, including food processing or marines.

Carbon Steel Unions:

Carbon steel is typically used in pressure applications where high strength and durability are mandatory. These might require certain coatings to prevent rusting.

2. PVC and CPVC Unions:

Thirdly, for the plumbing of residences, PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) are used. Plastic is lightweight, corrosion-resistant, and suitable for hot and cold water use. They become very popular in swimming pool installations and irrigation systems.

3. Compression Unions:

Compression is a compression fitting type that does not use soldering or welding for a tight, safe connection. They are great for applications where quick, reliable connections are required, such as in refrigeration and HVAC applications.

Applications of Union Fittings:

Union Fitting:

fittings are very versatile and have their applicability in many industries due to the ease with which they can be handled. Following are some of the common uses of fittings:

1. Residential Plumbing:

In residential premises, fittings are widely used for connecting water supply, drainage, and heating pipes. Since they can easily enable disconnection, they are used primarily in places with frequent maintenance requirements.

2. Commercial Plumbing:

fittings, in commercial buildings, are mainly used for interconnecting larger diameter pipes in the heating, cooling, and plumbing systems. They are also applied to food service applications where quick disconnection of pipes for cleaning and maintenance is required.

3. Industrial Applications:

fittings are highly represented in the industrial area in applications such as chemical processing, oil and gas, manufacturing operations, etc. Their robust construction with high-pressure-temperature resistance capabilities makes them highly suitable for industrial applications.

4. HVAC Systems:

fittings are part of the HVAC systems because they help join the refrigerant lines and offer relatively easy access to the system for purposes of repair and maintenance. They are useful where the working temperatures and pressures might be different because they are suited for climate control applications.

Benefits of Union Fittings:

Union Fitting:

fittings have benefits that make them one of the most popular options in many plumbing and piping systems:

1. Easy Installation and Maintenance:

One of the most important advantages of fittings is that they are easy to install. Unlike welded or soldered connections, which often take time and involve specific skills, can be screwed together or even unscrewed in a few minutes. Such characteristic makes them ideal for maintenance work, where technicians can access pipes quite fast for either repair or replacement, without a long outage.

2. Versatility:

Fittings are available in virtually all materials and a variety of sizes. However, regardless of what your requirements might be, fittings perfectly complement either metal or plastic piping.

3. Durability and Reliability:

High-quality fittings are made to face pressure, temperature fluctuations, and corrosion. It ensures that they can offer excellent service for a long time, thereby preventing leaks or failures in your plumbing system.

4. Cost-Effectiveness:

Although a fitting might require somewhat more up-front cost than others, the ease of use and long lifespan can often translate to cost savings in the long run. The reduced need for maintenance and ease of replacing parts makes it a sensible investment.

How to Install Union Fittings:

Union Fitting:

fittings are pretty easy to install; however, some best practices will make sure the installation is successful:

1. Choose Suitable Size and Type:

The size of pipes to be connected should be decided by the size of the fitting; proper connection should be searched. Likewise, the type of material too depends on the application and surrounding conditions.

2. Use Thread Sealing:

The threads should be covered with thread sealant or Teflon tape in the installation of metal fittings to prevent leakage. Plastic is installed following the manufacturer’s instruction not to use any sealant as plastics are not needed for some of them.

3. Tightening Slowly:

After the nut has been put in, the nut should be tightened with a wrench for tightness but not over-tightened so as not to damage the fitting or the pipe.

4. Testing for Leaks:

Perform all joined parts to leak check after installation by turning on the water supply or pressurizing the system. Should you come across leaks, inspect the fittings once more and have them tightened correctly.

Union Fittings Maintenance:

Union Fitting:

For the fitting to be long-lasting, proper maintenance must be done:

1. Check occasionally:

Monitor the fittings for rust, wear, or leakage. This will warn you way back before massive problems.

2. Clean Connections:

All fittings must be kept clean as well as clear of debris in the surrounding areas. The collected dirt leads to corrosion, which deteriorates the integrity of the connection.

3. Replace Damaged Fittings:

Replace the fitting right away if you find any damage or wear on it to keep the integrity of your plumbing system in check.