Propane Fittings:

Explanation of Propane Fittings: A Comprehensive Guide

Propane Fittings are a significant fuel source widely utilized for heating and cooking purposes and used to power many devices in both homes and businesses.

For this fuel to be used safely and effectively, fittings and connections must be designed and manufactured so consumers are aware of them. Here, in this blog post, we are going to look at a few of the different types of propane fittings and their applications, safety considerations, and best practices for installation and maintenance.

What Are Propane Fittings?

Propane Fittings:

Propane fittings are specialized connectors, valves, and other accessories for the safe transport of propane from storage tanks to appliances. Since these fittings deal with high-pressure gas, they must be designed using strong materials such as brass, steel, or plastic according to their intended applications.

Parts of Propane fittings:

Propane Fittings:

- Connectors: These fittings connect hoses or piping to propane tanks or appliances. Connectors come in various shapes and sizes according to the application.

- Valves: Valves control the flow of propane through a system. They can be manual or automatic and are useful for safety and control.

- Adapters: Adapters permit various types of fittings to join with one another. For example, they may allow a flexible hose to connect a rigid pipe.

- Regulators: Regulators reduce the high pressure that exists in the propane gas in the tank to a usable pressure for appliances. They ensure that appliances receive a consistent and safe gas supply.

- Hoses: Propane hoses have been manufactured to be able to withstand the pressures of propane gas. They are usually reinforced and flexible, making them very ideal for use in various applications.

Types of Propane Fittings:

Propane Fittings:

1. LP Gas Connectors:

These connectors were designed specifically to be used on LP gas systems. They consist of several fittings which include:

- Quick Disconnects: The fittings allow for the quick disconnection and re-connection of propane the very common appliance in grills and outdoor heaters.

- Flare Fittings: They deform the metal to make a seal to make a leakage-free connection. The flare fittings are common in applications involving high pressure.

2. Compression Fittings:

Propane Fittings:

Compression fittings use a compressing mechanism to attain a tight fit. Most often, they are used when installing propane lines for equipment that includes stoves and water heaters. Compression fittings are known to serve for long periods and are reliable.

3. Threaded Fittings:

Propane Fittings:

Threaded fittings are commonly available in a variety of sizes and are most often permanently installed in propane systems. They include:

- NPT (National Pipe Thread): These are used widely in plumbing and sealing by threading. Hence, it is useful for propane.

MPT (Male Pipe Thread) and FPT (Female Pipe Thread) fittings are available to connect male and female threads. This connection may be tough in propane lines.

4. Hose Fittings:

These are used to connect propane hoses with tank appliances or other hoses. It can include:

- Hose Barb Fittings: These are attached to the hose so that they can offer a tight seal on the hoses. They are usually applied to low-pressure systems.

- Swivel Fittings: They allow the hose to swivel with much freedom hence reducing any kind of stress on the connection, which in return, prevents leaks.

5. Regulator Fittings:

Regulator fittings will attach the regulator on the propane tank to the rest of the system. They ensure that the correct pressure is delivered through the propane system.

Applications of Propane Fittings:

Propane Fittings:

It is used in a wide range of applications such as:

- Residential Heating: Because propane can be used to heat homes, it is an extremely popular choice. And so the boilers, furnaces, and water heaters are attached to the propane tanks with the help of fittings.

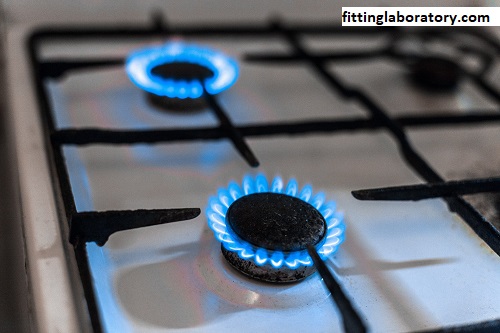

- Cooking Appliances: Many stoves, ovens, and grills use propane. To help these run safely as well as energy efficiently, it employs the help of specific fittings.

- Outdoor Equipment: Fire pits, outdoor heaters, and barbecues usually use propane fittings for easy connection to propane tanks.

Industrial Applications Propane has several industrial applications for instance forklifts, generators, as well as manufacturing processes. All of these require certain fittings to function appropriately and safely.

Safety Factors:

Propane Fittings:

The major safety factors with propane fittings include the following:

1. Proper Installation of Fittings:

- Propane-specific fittings only should be used. Failure to do this may result in leaks and a failed system.

2. Leak test:

Propane Fittings:

- After installation, always perform a leak test using a soap-and-water solution on all your propane

- fittings and connections. The presence of Bubbles indicates a leak which should be corrected immediately.

3. Regular Checks:

There are regular checks to be performed on all propane fittings and connections. Check for any signs of wear, corrosion, or damage, and replace the compromised parts immediately.

4. Follow Manufacturer Guidelines:

Propane Fittings:

Adhere to manufacturer requirements for installation and maintenance. Requirements differ among appliances, so adhering to safety and performance will be achieved by paying attention to each specific requirement of the appliance.

5. Professional Installation:

Propane installation can be pretty complex. If you have an extremely complex system, or you’re unsure how to perform the installation, it would be best to seek the services of a certified professional. The training and experience they have will ensure that connections are made safely, and the installation satisfies your local authority’s regulations.

Installation and Maintenance Best Practices:

Propane Fittings:

For safe and efficient operation, here are some best practices for propane systems:

1. Proper Sizing:

Ensure all the fittings, hoses, and regulators are appropriately sized for the propane system. Undersized parts could negatively influence the free flow of gas, while oversized components may not work properly.

2. Use Thread Sealant Wisely:

Propane Fittings:

Threaded Fittings When using threaded fittings, use the correct thread sealant to form a seal-tight connection. Teflon tape on flare fittings should not be used as it forms an invalid seal.

3. Secure Connections:

- All fittings should be tightened securely but should not be over-tightened, which may damage

- components or create stress points.

4. Store Propane Properly:

Propane Fittings:

For portable propane cylinders, store them upright and out of direct sunlight in a cool, dry area. Whenever storage of propane is done, it should be by the prevailing state and national regulations.

5. Learn:

Know the safety measures and the proper way to handle propane. Some credible institutions can guide you on how to handle, install, and use propane safely: the National Fire Protection Association (NFPA) and the Propane Education & Research Council (PERC).

Conclusion:

Propane Fittings:

Understanding propane fittings is extremely important for anyone who uses propane to heat or cook. The fittings are the cornerstone to guarantee the safe and efficient transportation of propane gas. Knowing all the different types of fittings, their applications, and the best installation and maintenance practices will mean one has done his part to ensure a safe environment for both himself and his family.

Never forget: if ever in doubt, it’s best left to the professional to install and maintain your propane system. With knowledge and caution, propane can be an efficient, safe, and reliable means of fueling your home or business. So go ahead, use that propane fitting, and enjoy the convenience and efficiency filling your life!